We help clients increase their asset productivity, improve process and equipment uptime through our systematic asset review. We deploy production enhancement and optimization techniques that can help our clients improve production in the shortest time possible

Boaz petroleum engineers have extensive field experience and unique analytical approach in analyzing flow in porous media up to delivering oil to the sales point and have unearthed optimization opportunities which otherwise did not seem to exist. Through detailed analysis of reservoir and production data, we identify candidates for remedial and workover activities. Our optimization analysis covers reservoir deliverability, inflow and outflow potential of the wells, artificial lift optimization, well completion designs and well integrity.

Boaz has unique expertise in the evaluation, selection, design and installation of Multiphase pumps in optimizing production from oil wells.

Information is power. Boaz empowers its clients with valuable information to solve their reservoir and production challenges. Through our cutting-edge technologies, we run reservoir-oriented surveys to diagnose these challenges and advise clients on the possible solutions. The technologies include Quad saturation, noise logging, and thickness quantification logging.

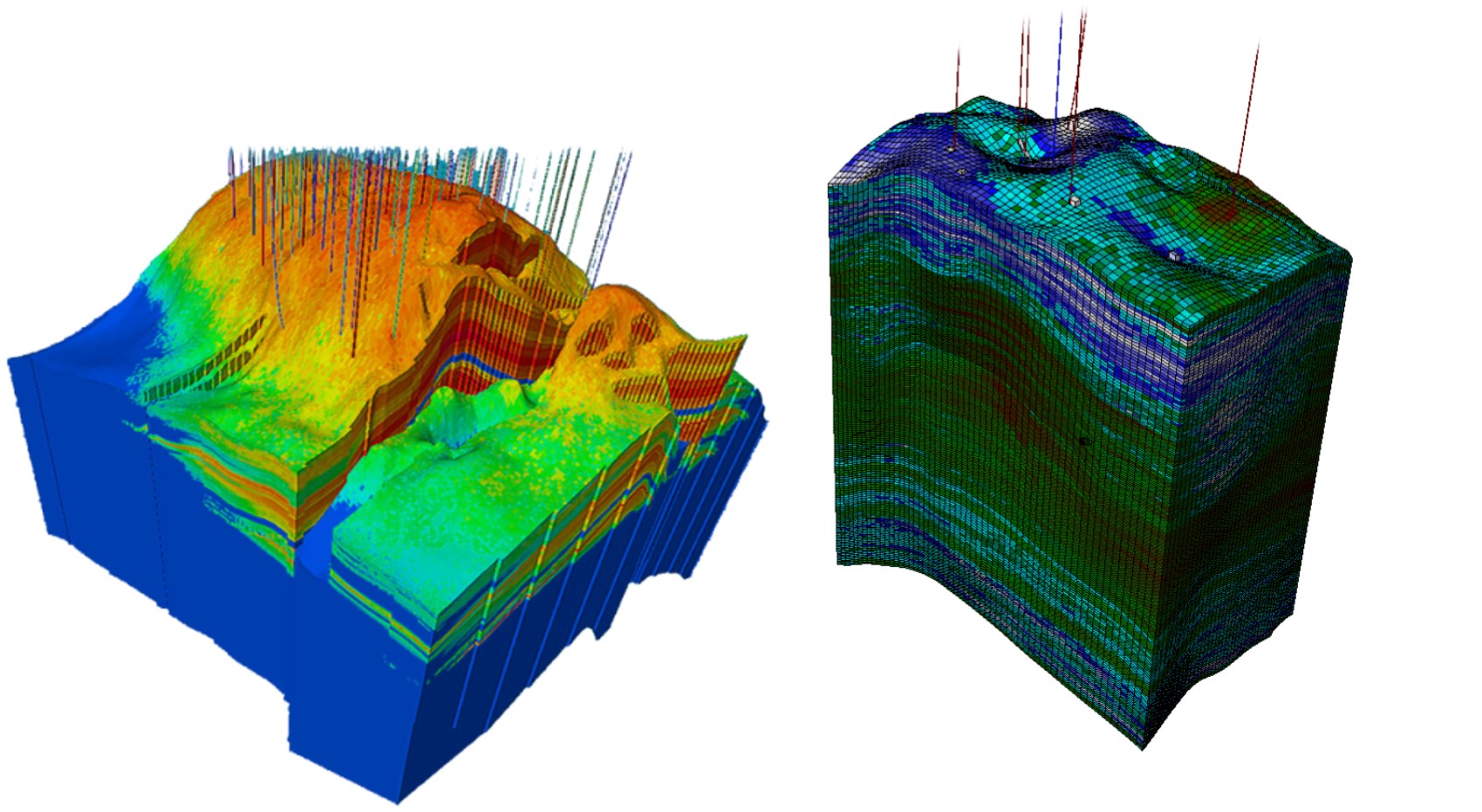

At Boaz, we provide our clients with reservoir management solutions throughout the field life. This is because of our multidisciplinary approach to solving reservoir and production challenges. Our approach comprises geological modelling, systemic field surveillance planning, dynamic reservoir simulation, pressure transient analysis, reservoir and well performance evaluation. We do not stop there. We also help clients with implementation of recovery techniques (simple and advanced) with the objectives to increase oil & gas production, maximize recovery, reduce risk, minimize capital expenditures, minimize operating costs, & maximize profitability.

As the fields get matured, oil production declines, water cut increases coupled with the challenge of handling the produced water. Produced water is believed to be a major disposal issue with associated costs. Over the years, the E & P companies have ways of managing the water by treating it to meet environmental legislation before disposing it. One of the ways to dispose produced water is by re-injecting it into the formation, and the other option is re-injection for pressure maintenance. But there remains a major challenge of monitoring significant parameters throughout the oily water separation and disposal process.

Boaz, in partnership with JORIN, has a unique Process Insight Technology (called Process Imaging) in helping E & P companies better monitor these major parameters and thereby providing them better levels of control of oil water separation process. Process Imaging uses an online image analysis technique to simultaneously provide information on the particle and droplet size distributions and the relative concentrations of both oil and solids in produced water. The ability to monitor significant parameters throughout the oily water separation and re-injection process allows real-time decisions to be taken, offering the opportunity to optimize the re-injection process with a view to achieve better injectivity. This unique approach will lead lower disposal costs, reductions in maintenance requirements to process, and increases in injectivity/well operational time between interventions.

Boaz, in partnership with Jorin UK, offers surface production process optimization services to its clients using the Process Imaging unique imaging technology.

Surface Production Process Optimization insight service covers oil and gas fluid behaviour during drilling/completion, production, sea water injection, waste-water treatment and produced water re-injection projects.

With a forward thinking approach, Boaz provides deep insight for better appraisals of exploration and production assets from exploration stage through the production systems up to the export terminal. Together with its AI partner (Data Science Nigeria), Boaz uses top-level petro-technical expertise in combination with heavy-duty mathematical algorithms to provide bespoke Artificial Intelligence (AI)-driven geo-engineering solutions to solve hydrocarbon exploration and production challenges. The solutions (ranging from surface to subsurface) can be customized to help our clients understand better their assets, quicker decisions and maximize ultimate hydrocarbon recovery.

Our innovative strategies for integrating the reservoir performance to the entire production systems (wellbore, and surface facilities) provide operators with the ability to make production system performance forecasting with ease, and enhance informed and fast decisions on production allocation and scheduling.

We carry out system modeling and simulation, optimization analysis of wells and networks, de-bottlenecking of complex production systems using petro-technical software combined with creative thinking leveraging AI capabilities.